團隊研發(fā)成功的廢鉛酸蓄電池資源清潔再生全套系統(tǒng)

湖南教育電視臺報道團隊研發(fā)成功的廢鉛酸蓄電池資源綠色再生技術

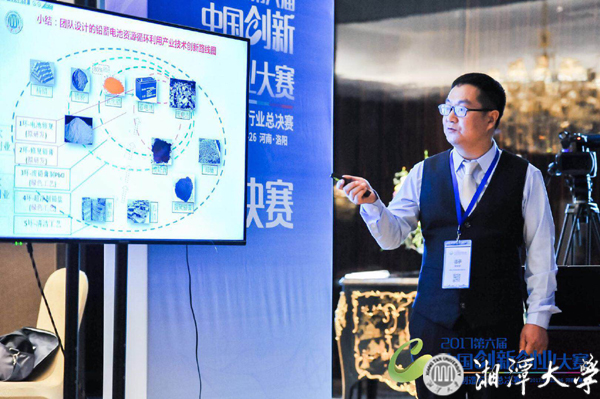

團隊負責人張俊豐教授

湘潭大學與湖南江冶機電科技股份有限公司建立了穩(wěn)固而深入的產(chǎn)學研用合作關系,組建了高效協(xié)同的“廢舊鉛酸蓄電池資源循環(huán)理論與技術裝備”研究團隊,涵蓋了環(huán)境科學與工程、化學、機械工程等學科領域,團隊成員包括湘潭大學的張俊豐教授、曹靖副教授、黃妍教授、汪形艷教授、肖啟振教授、舒洪波副教授、陳洪波博士、田科博士等,湖南江冶機電科技股份有限公司的王振云、范偉、陳彪等。

團隊圍繞“三次創(chuàng)新、五環(huán)遞進”的完整鉛蓄電池資源再生產(chǎn)技術創(chuàng)新路線,經(jīng)過五年多的技術攻關,成功研發(fā)了在國內(nèi)再生鉛行業(yè)中領先的廢舊鉛酸蓄電池“機械破碎分選—鉛膏預脫硫—低溫熔煉”等主要工藝環(huán)節(jié),研制的全套“清潔再生”技術裝備在國內(nèi)大面積推廣,行業(yè)占有率超過80%,并出口伊朗、印度、香港等地。團隊在鉛資源再生領域具有良好的人才和條件基礎,獲批了“湖南省鉛鋰電池資源高效循環(huán)利用工程技術研究中心”和“湖南省企業(yè)技術中心”等兩個省級創(chuàng)新平臺。

目前,團隊正在“清潔再生”技術裝備的基礎上持續(xù)創(chuàng)新和開發(fā)“綠色再生”技術裝備,已經(jīng)取得重要突破,將實現(xiàn)廢鉛膏銨法脫硫并高效益利用脫硫副產(chǎn)物的行業(yè)性技術突破,也將實現(xiàn)脫硫鉛膏免冶煉深度資源化的行業(yè)性技術變革。在“綠色再生”技術裝備成功產(chǎn)業(yè)化之后,團隊將攻關“原位修復”技術,進一步縮短廢鉛蓄電池的資源化流程,提高行業(yè)效益的同時更好地保護環(huán)境,踐行綠色發(fā)展。

Waste Lead-acid Battery Resource Cycling Theory and Technology Equipment Innovation Team of Xiangtan University

Xiangtan University and Hunan Jiangye Electromechanical Technology Co., Ltd. have established a cooperative relationship, and formed a highly effective and collaborative scientific team of theoretical research and technical equipment innovation for the recycling of spent lead-acid batteries, which covers the fields of Environment, Chemistry, Biology, Machinery, and Information Industry. The core members of the team are Prof. Zhang Junfeng, Prof. Cao Jing, Prof. Huang Yan, Prof. Wang Xingyan, Prof. Xiao Qizhen, Prof. Shu Hongbo, Dr. Chen Hongbo, Dr. Tian Ke from Xiangtan University and Wang Zhenyun, Fan Wei, Chen Biao from Hunan Jiangye Electromechanical Technology Co., Ltd.

The team proposed a “Three Innovations - Five Rings Progression” new technological route for the recycling of spent lead-acid batteries. After five years of hard work, the team successfully developed a complete system to deal with waste lead-acid batteries including “Mechanical Fragmentation - Paste Pre-desulfurization - Low Temperature Smelting”. This technology and equipment has not only been widely used in China but also exported to Iran, India, Hong Kong and other areas, and market share reaches up to 80%. The research team received a lot of honors and was granted two provincial innovation platforms “Hunan Lead-Lithium-Ion Battery Resource Efficient Recycling Engineering Technology Research Center” and “Hunan Enterprise Technology Center”.

The researchers have made important “green regeneration” technology and equipment breakthroughs in the desulfurization of waste lead paste with ammonium and also achieved great progress in free smelting method for lead recycling. In the future, the team will tackle the problem of “in-situ remediation” to further shorten the recycling process and improve the efficiency of the waste lead-acid batteries recycling industry, and the new technology and equipment will make a great contribution in protecting environment and practicing green development.

(環(huán)境與資源學院)